Incinerators are used when flaring is not a viable option. The combustion efficiency of an incinerator is known to be over 99% which is higher than a flare. Plus, they are more suitable for applications involving carcinogenic gases like BTEX and H2S applications. Incineration of waste gas products may not be a new concept for the oil and gas industry however, in recent years the design and technology have resulted in optimal performance, increased reliability and reduce capital and operating costs for operators.

Positive Points:

- No smoke, No Odor and No visible flame

- Offers complete combustion, so there is no un-combusted gas.

- It can combust heavy gases and eliminate odors typically caused by odourizers or mercaptans.

- Can be used within 500 meters of residences.

Negatives Points:

- Incineration produces CO2 as a GHG.

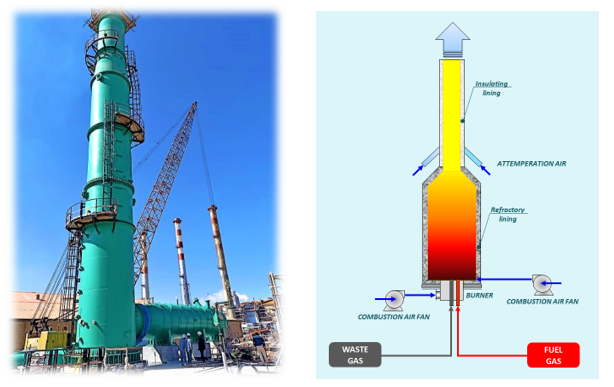

One of the important specifications for incinerators is the height of the chimney stack and its performance. Sufficient height is usually required on the chimney to extend above any surrounding buildings or land in the immediate vicinity, and this is often a regional requirement to ensure that any gases and emissions are adequately dispersed. The operating temperature of the incinerator should always be checked to ensure complete combustion. At least 850 °C should be considered as the working temperature of modern, efficient and effective waste incinerators. Internal fireproof refractory is considered for preventing the heat transfer inside the incinerator to the outside and protecting the operators. The chimney, which is covered with fireproof insulation, is installed on top of the combustion chamber. The waste burner consists of a fuel gas burner and a waste gas burner. The gas burner works with high pressure fuel and combustion air supplied by a fan. The additional air needed to maintain the operating temperature when burning the waste gases is provided by the fan through the channel and several nozzles. For safety, depending on the characteristics of the waste gas, a flame arrester can be installed on the waste gas line to avoid any risk of backfire from the burner. The burner control system (BMS) automatically performs fuel supply and flame control and secondary air to maintain the working temperature in the chamber. Adjusts ignition. With its technical knowledge in this field, Chaman Company has been able to complete the design of the waste incinerator considering the optimization of fuel consumption.

Get product catalog