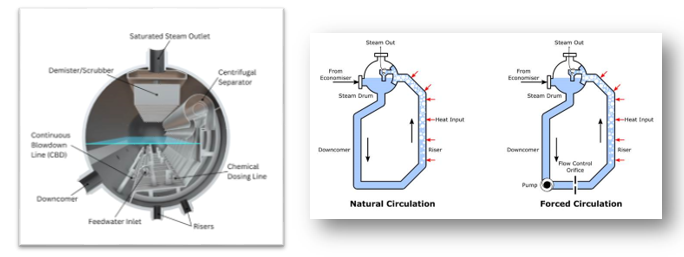

The steam drum is used to generate clean, dry steam and to provide access to saturated water. This equipment is utilized in boilers, various types of process furnaces, reformers, and cracking units. In different furnaces, the process fluid or flue gas resulting from combustion can act as the heating medium to generate steam. The diagram below illustrates the various components of a steam drum.

Feed Water: Refers to the amount of water that is fed into the steam drum and has not yet entered the furnace or boiler.

Downcomers and Risers: These are the water and steam flow paths designed to allow water to flow into the furnace (or boiler) and toward the steam drum.

Two common mechanisms are used to separate steam and water: 1) **Centrifugal Separation** – where liquid and vapor phases are separated using centrifugal force. 2) **Gravity Separation** – based on differences in weight and density. Also, based on the fluid flow inside the steam drum, it can be categorized into **natural circulation** and **forced circulation** types.

Get product catalog