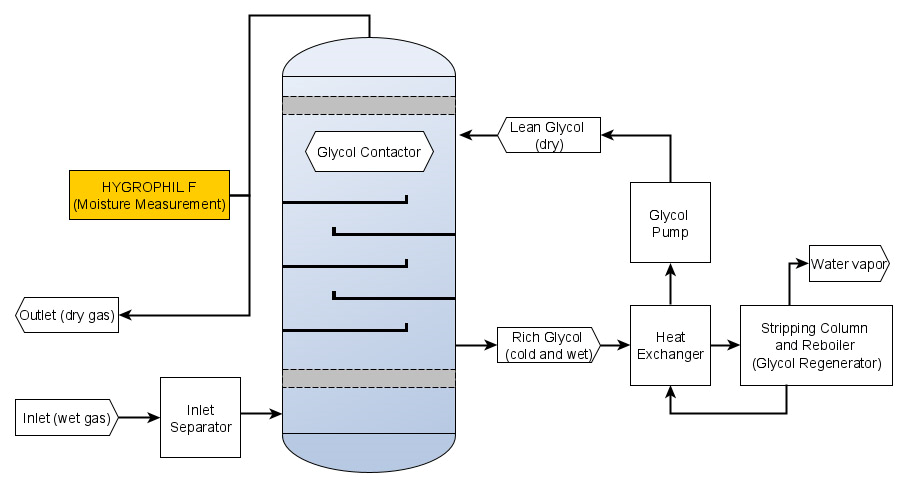

Natural gas dehydration package is designed and implemented with the aim of reducing the amount of water vapor in natural gas. In order to prevent corrosion in the process of natural gas transmission or the requirements of its use in downstream units, the water content in natural gas must be reduced, which can be achieved by dehumidifying natural gas and water dew point depression. Absorption method with liquid absorbent is one of the most common natural gas dehydration methods. In this method, the water vapor in the gas is absorbed by a liquid solvent stream. Glycols are suitable solvents for this purpose due to their high efficiency, easy and economical regeneration, non-toxic and non-corrosive properties, and low absorption of hydrocarbons. Among them, Tri-Ethylene Glycol is the most common solvent used in natural gas dehydration units. The mechanism of dehydration packages with absorption method with liquid absorbent is based on one absorption step and one regeneration step. In the absorption stage, the moisture in natural gas is absorbed by the Tri-Ethylene Glycol solvent at high pressure and low temperature, and in the regeneration stage, water-rich glycol is regenerated at high temperature and low pressure and can be used again. The product of this unit is dry natural gas, the specifications of which are different based on the needs of each project.

Among the most important factors in Gas Dehydration, the following can be mentioned:

- Gas and glycol temperatures

- Gas flow rate and specific gravity

- Operating pressure

- Inlet water content

- Glycol circulation rate

- Glycol purity

- Mechanical or chemical issues (foaming)

- Corrosion cause by NaCI, H2S, and CO2

Reliable humidity measurement in the outlet gas is essential to ensure proper dehydration to meet sales gas criteria or prevent hydrate formation in the connected pipelines.

Simplified Flow Diagram of Glycol Dehydration unit

The design and engineering of Glycol Dehydration and Regeneration plants covers an important part of Chamaan company's activities. Chaman company, having the design technology of Gas Dehydration and Glycol Regeneration Packages, has so far carried out several Dehydration projects in Iran which had different design aspects based on the characteristics of wet gas, product dry gas, operating temperature and pressure and the sourness of natural gas.

Get product catalog